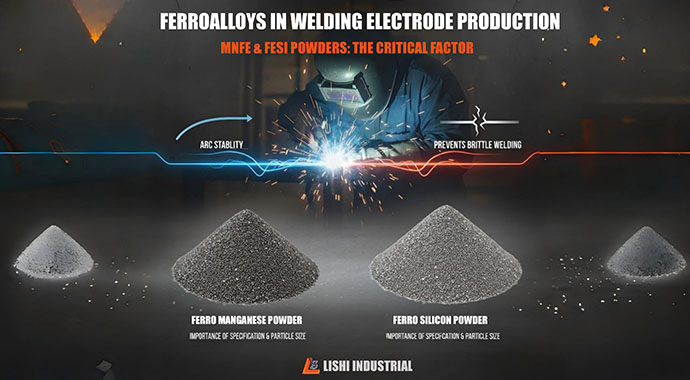

Are you looking to optimize the quality and efficiency of your welding rod manufacturing? The secret often lies in the raw materials you choose. Let’s talk about two indispensable alloys in electrode production: Ferrosilicon (FeSi) and Ferromanganese (FeMn) powder. These are not just additives; they are the backbone of high-performance welding electrodes.

Ferromanganese is primarily used as a powerful deoxidizer and desulfurizer. It is crucial for enhancing the mechanical properties of the weld metal, specifically boosting tensile strength and hardness. Meanwhile, Ferrosilicon acts as a stabilizer. It improves the fluidity of the molten metal, prevents porosity, and ensures a smooth, stable arc during the welding process. Together, they create welds that are cleaner, stronger, and more reliable.

However, consistency is key, and this is where Chemical Composition and Particle Size Distribution become non-negotiable. If the chemical balance is off, the weld becomes prone to cracking. If the particle size is inconsistent, the flux coating mixes poorly, leading to unstable arcs and spatter. To illustrate the real-world impact of these factors, let’s look at two revealing case studies.

Case Study 1: The Arc Stability Crisis

A mid-sized manufacturer of low-hydrogen electrodes was facing a recurring customer complaint: "erratic arc behavior" and excessive spatter during welding. Despite their coating formula being theoretically correct, the production line was yielding inconsistent results.

Upon investigation, we found the issue lay in their Ferrosilicon powder supply. While the chemistry was within limits, the Particle Size Distribution (PSD) was too broad. The powder contained a significant amount of "fines" (ultra-fine dust). This caused the powder to segregate from the heavier binding materials in the coating mix. When the rod was welded, the fine dust burned off too quickly, causing the arc to fluctuate.

The Fix: The manufacturer switched to a supplier that guaranteed a tighter PSD (specifically, sieving to retain particles between 40-200 mesh and eliminating dust). The result? The homogeneity of the coating improved immediately, leading to a perfectly stable arc and a 30% reduction in customer returns.

Case Study 2: The Brittle Weld Failure

Another client producing structural welding rods was experiencing sudden weld failures during stress testing. The welds looked visually acceptable, but they were brittle and cracking under pressure.

An analysis of the raw materials revealed that their Ferromanganese powder had high variability in Carbon and Phosphorus content. Even though the average was "passable," individual batches had spikes in Phosphorus, which caused cold cracking in the final weld structure.

The Fix: The client implemented a stricter Quality Control (QC) protocol, requiring a certificate of analysis (CoA) for every batch of FeMn powder, ensuring Carbon (<0.1%) and Phosphorus (<0.03%) levels were strictly controlled. This chemical consistency eliminated the brittleness issue, restoring the structural integrity of their welding rods.

Conclusion